Have you experienced any problems as follows?

Paint does not last long.

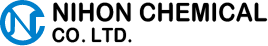

In general painting, since paint is applied on a metal surface with mill scales (oxidative products remain on metal sheets when they are produced), rust develops from the boundary of mill scales over time and this rapidly damages paint.

Shot blasting is a suitable process to prevent

from the acceleration of rusting and extend the life of paint

A system for extending the life of paint

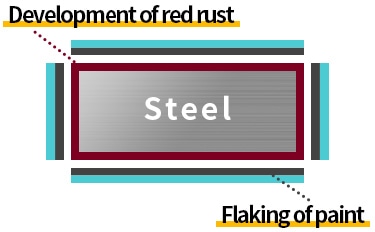

State of steel during manufacture

State of steel during manufacture

When steel products are produced, they have mill scales (oxidative products remain on metal sheets when they are produced). In order to remove the oxidative products, shot blasting is conducted.

POINT- Painting steel products without first removing mill scales allows rust to develop at the boundary areas.

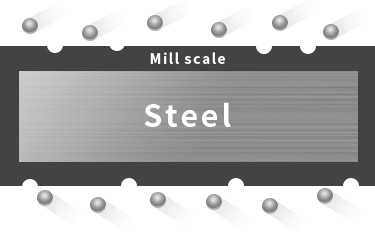

Conducting shot blasting

Conducting shot blasting

A large number of small iron balls (abrasives, shot balls) are blasted from the shot blasting machine at high speed.

After shot blasting

After shot blasting

Mill scales and other foreign objectsare removed from the surface and the impacts of shot blasting create create small craters on the surface of iron.

Painting

Painting

Since mill scales have already been removed, rust does not develop below paint.

POINT- Flaking of paint does not occur even after time has passed.

- An uneven surface allows for good adhesion of paint on steel products.

When steel products

are shot blasted

Paint lasts a long time!!

Shot blasted steel products are used in areas where steel needs to be protected by a coating for a long time.

This technology is used in bridges, ships, power plants, LNG tanks, marine structures, as well as aesthetically-designed buildings.

"Shot blasting can be applied

to a variety of steel materials"

As Nihon Chemical has 8 factories (9 production lines) throughout Japan,

we are capable of processing a variety of products in different sizes and shapes.

For example, we have production lines equipped with machines capable of performing accurate surface treatment for

thin steel materials (thickness: 2.3 mm) and large steel structures (height: 1,000 mm) of various shapes.

The distortion of 2.3 mm thick steel materials cut from hot-rolled steel coils can be controlled optimally by shot blasting using our unique technology.

Large steel structures can be managed by manual shot blasting.

Thin Product

Steel materials cut from hot-rolled coils

(Minimum thickness: 2.3 mm)

* We have experience in processing 2.0 mm products. Please consult us.

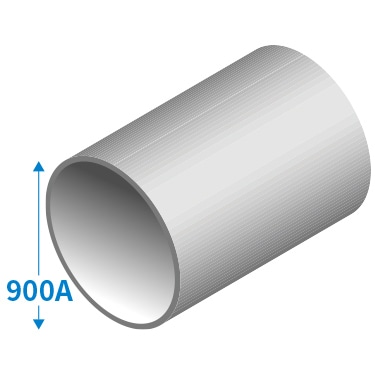

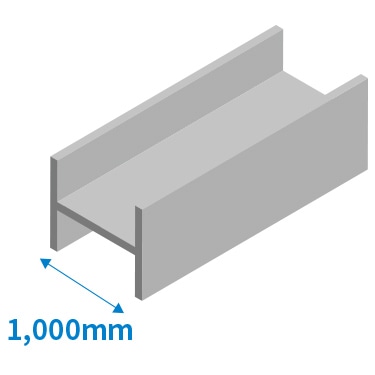

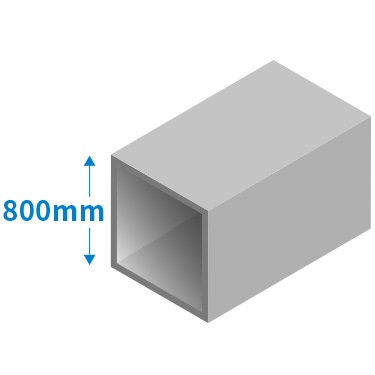

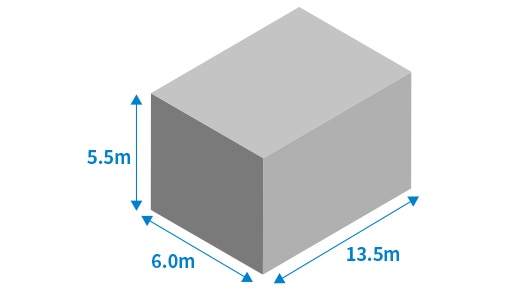

Large Product

Pipe

H-beam steel

Square pipe

Shot Blasting for Steels Products

* Weight of a single product: 10 t